Edgetec S-200 series at Black Label

Karl’s decision to focus on contract manufacturing for others mean he needed the capacity to provide a complete solution for the commercial contracts he has. A key component was the need to work with high-gloss panels, as well as large portfolio of cabinets in an even wider range of colours and finishes. “With our old edgebander it took longer to clean up the edges after processing than it did to do the processing in the first place” says Karl. “We needed something to provide a consistent finish for a wide variety of materials, as well as delivering a top-quality finish on high-end product.”

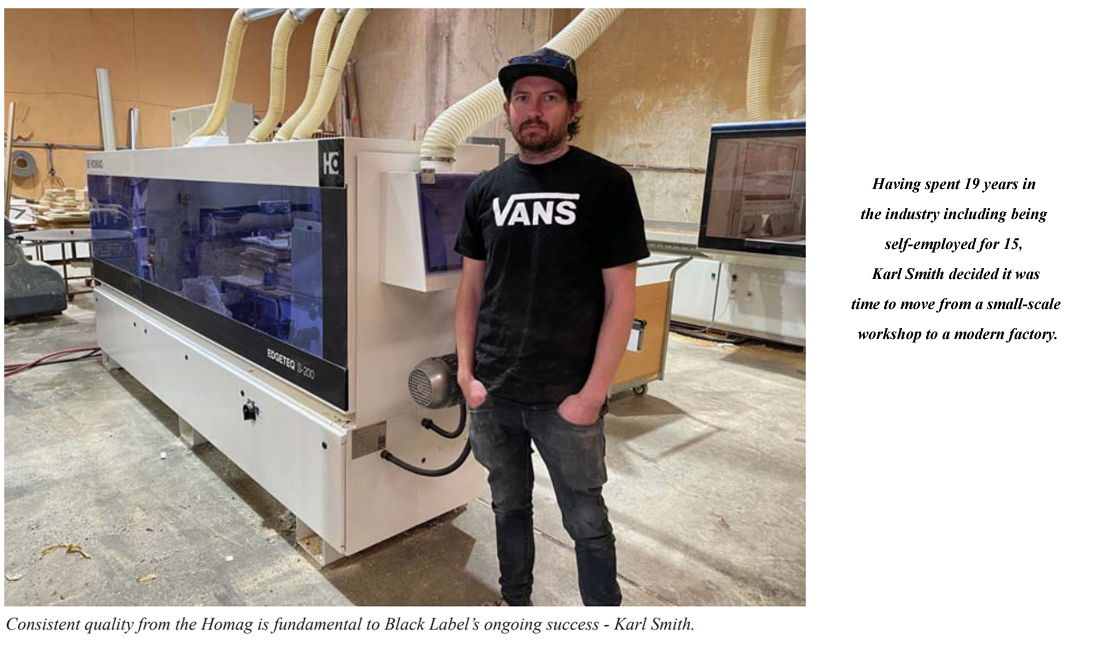

Black Label invested in an Edgetec S-200 series edgebander from Jacks – model 1130 AT. Offering Homag’s airTec system for working with laser-edged tape, the 1130 AT also features pre-milling, quick-change gluepots, top and bottom trimming, corner rounding, scraping and buffing. While the airTec system provides the capacity to work with high-gloss and satisfy a specific segment of the market, Karl also opted for two gluepots, meaning the changeover from clear to coloured for conventional tape is quick and simple.

Read the full Joiners Magazine article here