- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

The compact hot-melt Edgebanding solution for quality and performance.

Maximum performance in the smallest amount of space! Your Felder G380 occupies a total length of only 2.8 metres ensuring precious space is not unnecessarily wasted in your workshop.

The compact design of processing units ensures you still receive a fantastic result from this space saving edgebander. In addition to the compact size, the 8m/min feed speed ensures a high throughput of workpieces.

Make an enquiry about the Felder G380 Edgebander

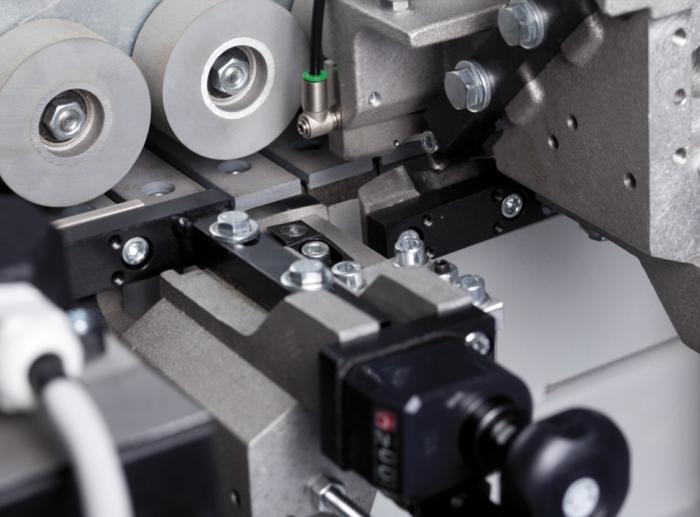

Pre-milling Unit

The two diamond tipped milling heads rotate in opposite directions preparing a perfectly straight and perpendicular workpiece edge to which the edge material is glued. The pre-milling unit also removes imperfections such as chips or tears in the melamine along the edge to improve the appearance and quality of the finished edge.

• Pre-milling depth 0 – 2mm

Operating Panel

A clear and easy to understand control panel is found on the G380. Each unit can be individually selected from the panel.

The G380 controller automatically engages a stand-by temperature if the machine is idle for 20 minutes. This maintains the integrity of the glue by keeping it at the application temperature for the shortest possible time, preventing ‘cooking’ the glue

Pressure Bar Adjustment

The large scale assists with setting the pressure bar height to match the workpiece thickness both accurately and quickly. • Workpiece thickness 10 – 45mm.

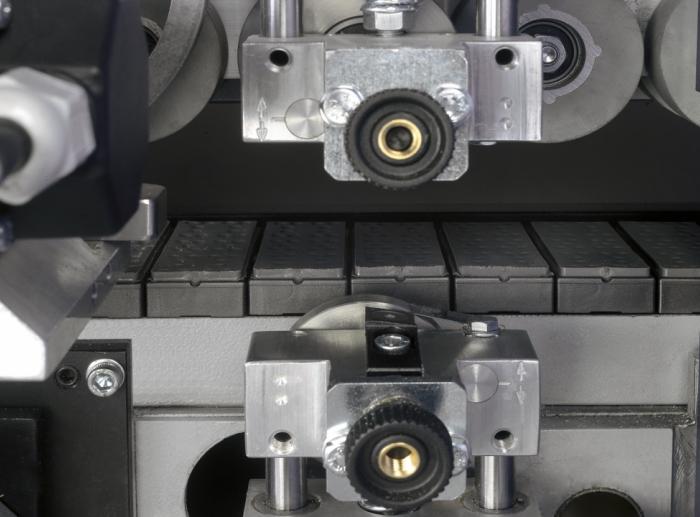

Chain Feed

Precise work-piece feeding with chain and drive rollers in an offset formation, leaving no scratches on the workpiece surface.

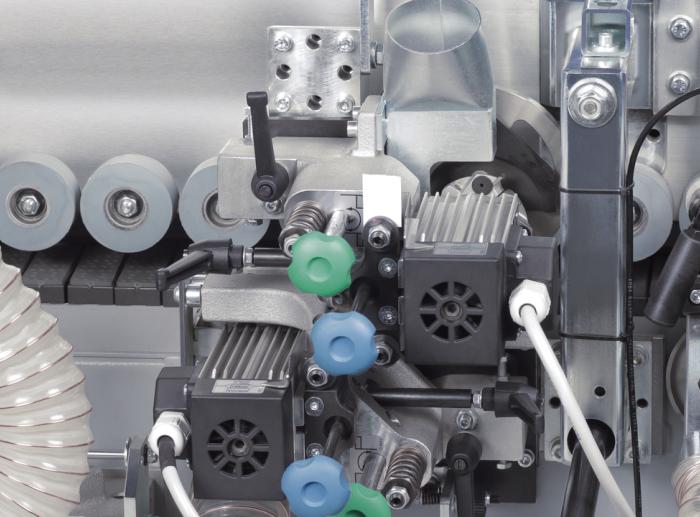

Quick Change Glue Pot

The Teflon coated glue pot can be quickly and easily changed. This enables glue colour changes to match the colour of material being edged.

Multi-function Trimming Unit

The G380 features a compact multi-functional top & bottom trimming unit. The overhanging upper and lower edges are trimmed flush to the surface of the workpiece with upper and lower, 4-knife cutterblocks. 3 trimming finishes are available: 1. Flush 2. Bevel 3. Radius

Glue Joint Scrapers

This unit removes any remaining glue residue from the panel, leaving a perfect finish requiring no extra finishing.

Radius Scraping Unit

The radius scraping unit removes cuttermarks to the top and bottom edges left behind by the trimming unit.

The radius scrapers remove a paper thin scraping of the edge material, smoothing out the edge to improve appearance.

• Compact modern edgebanding technology in just 2.8 metres of workshop space

• Centralised control panel for a premium level of user comfort

• Heavy-duty chain feeder ensures optimal results from all units

• Pre-milling for the prefect preparation of the edge prior to tape application

• Teflon coated gluepot with 1.2kg glue capacity for larger runs

• Quick change glue-pot system allowing colour matching of glue to edge material

• Felder “Quick-Set” system for pre-set adjustments of processing units

• Combined end trim and profile trimming unit for either flush trim or rounding of corners

| Panel thickness | 10 - 45mm |

|---|---|

| Tape thickness | 0.4 - 3mm |

| Minimum workpiece length | 210mm |

| Minimum workpiece width | 70mm |

| Feed speed | 8m/min |

| Weight | 450kg |

Specifications are subject to change without notice.

G380 Edgebander

|

P200 Edgebander (secondhand)

|

|

|---|---|---|

| Weight | 450kg | 210kg |

| Panel thickness | 10 - 45mm | 10 - 45mm |

| Feed speed | 8m/min | 3.5 - 5m/min |

| Minimum workpiece width | 70mm | 90mm |

Want to know more? Visit Felder's youtube channel for videos featuring the Felder Group range of machines.

Felder offer woodworking machine specialists for industry, business and hobby use. Tradition – Innovation – Perfection.