- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

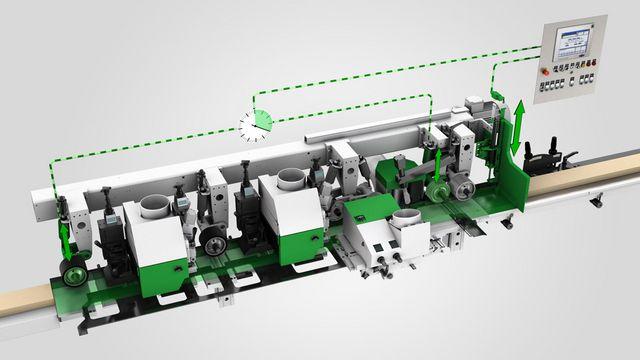

The valuable moulder for optimum profitability.

Ultimate design, perfect processing down to the last detail, typical WEINIG: with the Powermat 1500 WEINIG offers an exceptional machine as a standard model. Behind every high performance machine there must be a design concept that puts you in a leading position to control costs, guaranty scheduled delivery times and cater to your customers' wishes. With the Powermat 1500 you will experience the full capability of a WEINIG moulder.

With this exceptional state of the art machine standard the Powermat 1500 offers outstanding ease of use and a maximum of profitability. Decades of experience have influenced the development of this machine. Supplemented by useful extras the Powermat 1500 can be perfectly adapted to your individual needs. The result: a machine coping even with challenging applications and delivering top quality. The scope of applications even goes beyond the processing of solid wood only.

Make an enquiry about the Weinig Powermat 1500 Planer Moulder

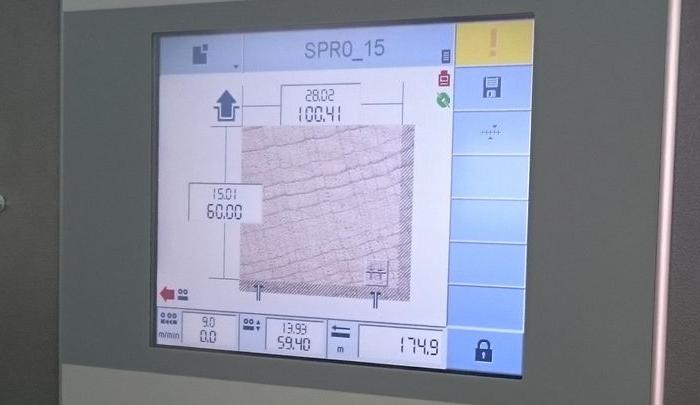

High level of repetition precision

The machine controls are able to store the setting values of the machine for any profile. If you want to produce the same profile again at a later date, the controls retrieve the setting values. This makes the setup process so much easier. It also means improved safety for the operator since the risk of errors is minimized.

High resource efficiency

The preservation and efficient use of resources is one of the strongest trends of our time. In the past WEINIG has always taken this aspect into account when designing new products and now even more so in the new Powermat generation. In addition to the use of energy efficient IE3 motors special attention was given to develop a new concept for the dust extraction system. The optimized flow of dust and chips reduces the performance requirements of the dust extraction system and therefor reduces the consumption of energy.

Outstanding surface quality

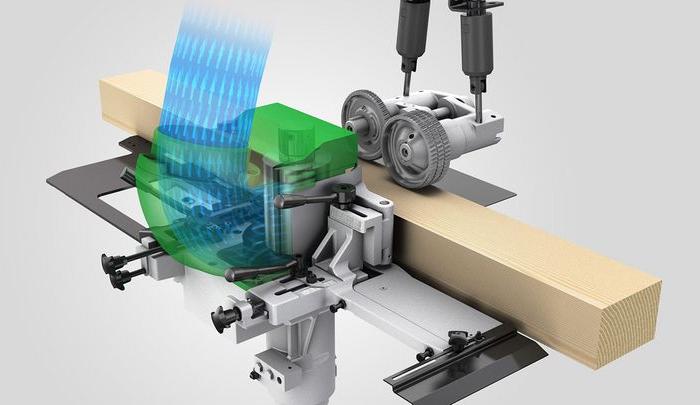

The Powermat 1500 guarantees optimal interaction of tool and machine. From the cast-iron frame to the machine table and spindles, WEINIG represents optimal machining quality. This quality means that the process runs as smoothly as possible and this is reflected in the surface quality of the work pieces. This accuracy also guarantees precise profile production.

Workpiece monitoring

The workpiece monitoring automatically detects whether there is a workpiece inside the machine or not. This allows dimensional changes while the machine is running. You benefit from simple operating and time savings.

User-friendly

Machine setup should be as quick and convenient as possible to minimize downtime. The Powermat 1500 offers good accessibility into the machine interior and is highly user-friendly. All the necessary settings can be made from the front. This increases safety and saves time!

Sustainable machine concept

Like all WEINIG machines, the Powermat 1500 is based on the principle of sustainability. By this, we mean machines with long service lives, characterized by high reliability and safety as well as efficiency in terms of energy and material resources.

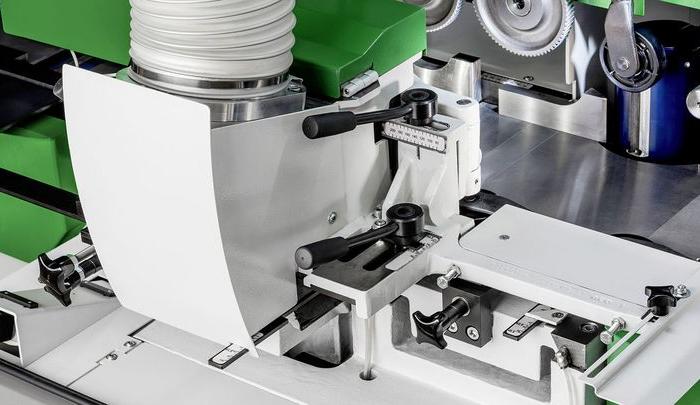

Savings in setup time

One of the primary benefits of this operating concept lies in reducing setup and idle time to a minimum. Additional potential in this area can be realized through proven optional equipment such as the PowerLock tool clamping system. With this, the full flexibility of the Powermat can be realized and even frequent tool changes or short production runs will not have a negative effect on the economic efficiency of your production.

Excellent safety features

The outstanding accessibility of the Powermat enables all adjustments to be performed from the front side of the machine with ease - a large number of these are even wrench-free. Through the clear view and practical layout of the operating elements within the enclosure the operator's safety is ensured. During production the access door of the Powermat is locked according to safety regulations. Full view of the working area is assured through the large window.

| Working height | 10 - 160mm (200 optional) |

|---|---|

| Working width | 20 - 230mm (260 optional) |

| Feed speed | 5 - 40m/min |

Working height min./max. 10/160 mm

Working width min./max. 20/230 mm

260 mm working width Option

310 mm working width Option

200 mm working height Option

7,000 rpm (except first bottom spindle) Standard

8,000 rpm Option

12,000 rpm Option

Operating concept Comfort Set Standard

Memory Plus Standard

PowerCom Plus Option

Electronic displays Standard

CNC-controlled axis adjustments for spindles and feed beam Option

Pressure shoe in front of top spindle, receding from the tool Standard

Max. tool diameter, horizontal spindles (not first bottom) 225 mm

Max. tool diameter, vertical spindles 200 mm

PowerLock tool holders Option

Universal tool holders Option

Frequency-controlled feed speed (standard) 5 - 40 m/min

MarathonCoating for machine table Option

Max. motor power on vertical spindle (standard - option) 5.5 - 15 kW

Max. motor power on horizontal spindle (standard - option) 5.5 - 37 kW

Improved sound enclosure Option

Specifications are subject to change without notice.

Powermat 1500 Planer Moulder

|

Powermat 700 Planer Moulder

|

|

|---|---|---|

| Working width | 20 - 230mm (260 optional) | 20 - 230mm |

| Working height | 10 - 160mm (200 optional) | 10 - 160mm |

| Feed speed | 5 - 40m/min | 5 - 40m/min |

Visit Weinig's youtube channel >>

The whole world of solid wood processing with Weinig