- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

WEINIG Powermat 3000: Reliable, powerful, versatile

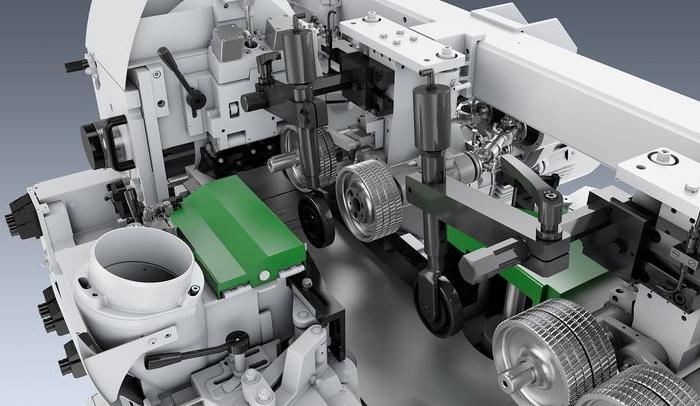

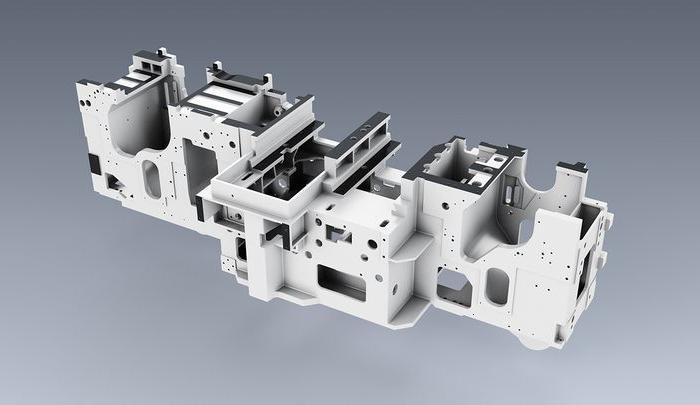

Knowledge, diligence and quality awareness: The Powermat 3000 is the result of the interaction of these factors. From the construction of the high-quality cast iron base to the programming of the intuitive control and the production of the high-precision spindles all the way through to the precise assembly of all elements. The Powermat 3000 offers ideal conditions for serial production with maximum surface quality.

The modular design and large number of options enables the most diverse applications. Not to mention excellent cost efficiency and resale value.

Regardless of the application, the Powermat 3000 can be adapted to your individual requirements in terms of quality, flexibility and performance.

The robust machine base serves to integrate high-quality components with convenient settings and intuitive machine control, resulting in a machine that is very easy to set up. For you, this means shorter set-up times, high operator safety, high machine availability and economical production - with legendary WEINIG surface quality.

Make an enquiry about the Weinig Powermat 3000 Planer Moulder

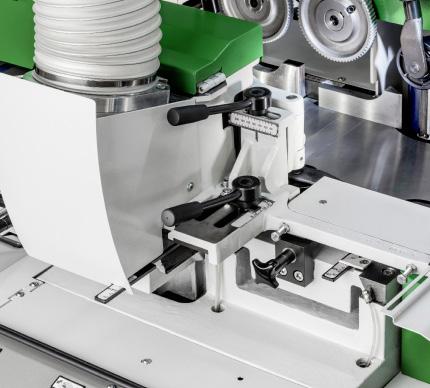

Ultimate ease of use

Machine setup should be as quick and convenient as possible to minimize downtime. The Powermat 3000 offers optimal accessibility into the machine interior and ultimate ease of use. All the necessary settings can be made from the front. This increases safety and saves time!

Enormous saving in set-up time

A major benefit of the new operating concept is the reduction of set-up time and downtime to a minimum. Proven options such as the PowerLock tool system offer additional potential in this area. This allows operators to make full use of the Powermat’s flexibility, and even frequent profile changes or small batch sizes do not represent a disadvantage for the economic efficiency of your production.

Rapid dimension and profile changes

With the help of the machine controls, adjusting the dimensions or profile is child's play. The controls specify the tools to be set up and the target values of the spindle position. The machine is positioned automatically, as required, using the CNC-controlled axes. In no time at all, the machine is setup and ready for production.

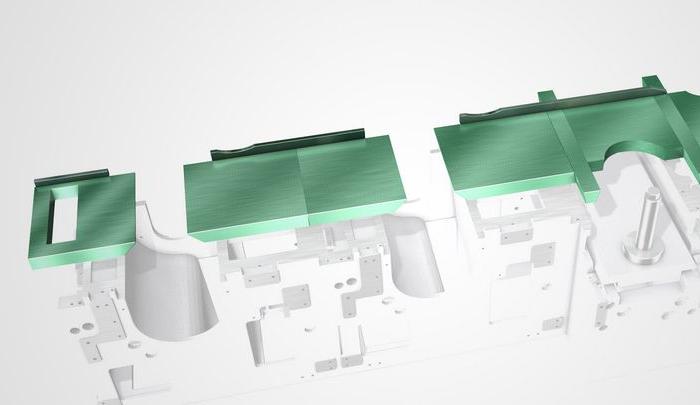

High wear resistance

The long-life MarathonCoating provides high wear resistance to the machine table and stop and thereby guarantees consistently good workpiece through-feed with low friction. This makes the Powermat 3000 ideal for demanding industrial applications.

Outstanding surface quality even at high feed speeds.

The Powermat 3000 guarantees optimum interaction of tool and machine. From the cast-iron frame to the machine table and spindles, WEINIG represents optimal machining quality. This quality means that the process runs as smoothly as possible and this is reflected in the surface quality of the work pieces. This accuracy also guarantees precise profile production.

Thanks to the use of joint technology, all knives on a cutterhead are brought into an identical cutting circle. This guarantees outstanding surface quality even at high feed speeds.

Sustainable

Like all WEINIG machines, the Powermat 3000 is based on the principle of sustainability. By this, we mean machines with long service lives, characterized by high reliability and safety as well as efficiency in terms of energy and material resources.

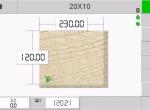

| Working height | 10 - 160mm |

|---|---|

| Working width | 20 - 230mm |

| Feed speed | 5 - 40m/min |

Specifications are subject to change without notice.