- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

The Profimat 50 from Weinig has arrived! Part of the all-new Profimat series, the Profimat 50 has been designed to offer small- to medium-sized manufacturers maximum performance and flexible production when planing and profiling all types of timber. With its robust cast-iron machine base and precision-machined spindles, the Profimat 50 ensures a high surface quality on all workpieces, while sitting comfortably within an 8.8sq.m footprint.

The robust moulder, which is fully customisable and offered with optional tool packages, has been designed to work up to 260mm wide – the width of a stair tread and, in many cases, a window board. The new model can be specified with five or six heads and powerful motors up to 15kW.

The five-spindle model has a frequency controlled feed speed of 30m/min and a spindle speed of 7,000rpm as standard with 8,000rpm available if 15-33% more production is required without any reduction in surface quality. The moulder also comes equipped with a manually adjustable 6mm lateral guiding fence, adjustable table plates and an easily adjustable fence after the right spindle. A driven table roller in the outfeed adds to the quality of the finished product.

Make an enquiry about the Weinig Profimat 50 Planer Moulder

Everything under control

The Profimat 50 is equipped with an intelligent control package for reproducible results at the push of a button – including a 10.1” display with intuitive user guidance.

The width and thickness are automatically set to a nominal dimension, or the machine can be adjusted manually.

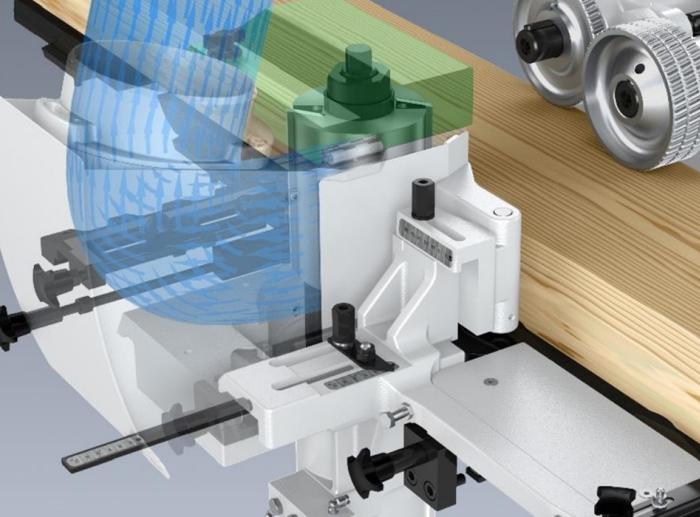

Straightening or surfacing

Weinig technology allows you to plane crooked or bowed work pieces perfectly without retooling. The first feed roller has vertical pneumatic adjustment without opening the safety hood, so you can choose to straighten timber or plane with the bow from the operator console.

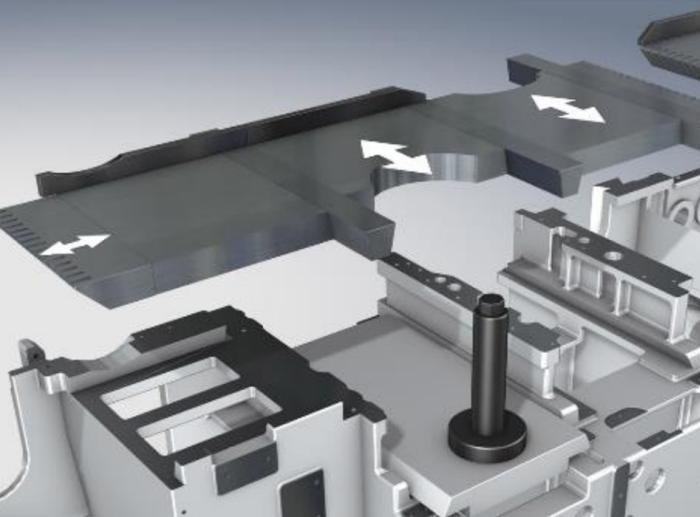

Feed system

Feed system features a frequency-controlled feed motor, main drive shaft, gear boxes and cardan shafts. There is separate adjustment and positioning of feed beam and top spindle. Feed rollers are quickly adjustable and 140mm in diameter for consistent surface contact. Central adjustment and positioning of feed beam together and top spindle makes setup swift. All feed rollers are Weinig Durofer pointed tooth rollers, self-cleaning, with depth limitation and quick clamping Advantages • Quick positioning of feed roller tracking • Quicker exchange of feed rollers

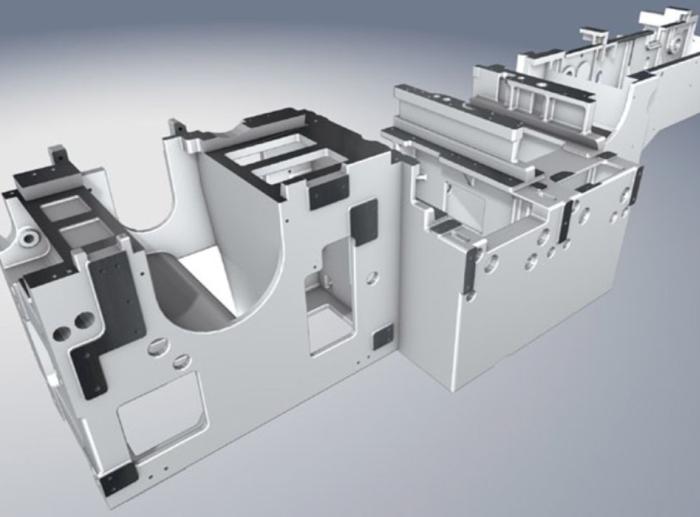

Machine frame

The Profimat 50’s compact design still features a heavy, robust and durable machine frame made from solid cast iron. Vibration is the enemy of a good finish. Cast iron has great vibration reducing properties and is the best material when mass and weight are needed. Advantage • High surface quality and reliability • Low space requirements

Positioning according to rulers

Rulers inside of the machine to accurately adjust pressure elements and guides • Specific, quick and simple setup • Reduction of setup times • Properly set pressure elements and guides play a deciding role in the quality of the finished products

Machine table and fence

Table plates and fence lip after the right spindle continuously adjustable to the tool cutting circle Driven table roller in the outfeed • Very good guiding of workpieces due to reduction of the notch in machine table and fence • Reduction of setup times • Properly set guides play a deciding role in the quality of the finished products

PLANING AND PROFILING WITH WEINIG QUALITY.

Features and customer benefits:

- Robust and durable machine frame from vibration-absorbing cast iron

- High ease of use and very good accessibility

- Integration of high-quality spindles

- Safety equipment according to latest standards

- High surface quality

- High ease of use

- Excellent surface quality

- High operator safety

| Working height | 10 - 160mm |

|---|---|

| Working width | 20 – 230 mm |

| Feed speed | 5 - 30m/min |

| Dimensions (W x D x H) | 2154 x 3550 x 1875 mm |

| Spindle Ø | 40 mm |

| Spindle speeds | Variable 5 – 30 m/min |

Specifications are subject to change without notice.

Profimat 50 Planer Moulder

|

Powermat 700 Planer Moulder

|

Powermat 1500 Planer Moulder

|

Powermat 3000 Planer Moulder

|

|

|---|---|---|---|---|

| Working width | 20 – 230 mm | 20 - 230mm | 20 - 230mm (260 optional) | 20 - 230mm |

| Working height | 10 - 160mm | 10 - 160mm | 10 - 160mm (200 optional) | 10 - 160mm |

| Feed speed | 5 - 30m/min | 5 - 40m/min | 5 - 40m/min | 5 - 40m/min |

Visit Weinig's youtube channel >>

The new Profimat. Planing and profiling in Weinig quality.

The whole world of solid wood processing with Weinig