- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

The Stenner ST100R is a familiar sight around the New Zealand timber industry. This workhorse is a highly engineered, compact and reliable band resaw that is particularly suitable for joinery workshops, furniture manufacturers, builders’ merchants and the many other woodworking establishments where quality, reliability and versatility are important factors. The machine incorporates a soft-touch digital pad allowing all major functions to be controlled from one point.

This is an ideal resaw as the main production machine in a smaller workshop, or a machine for offline flexibility in larger mills.

ST resaws require no pit or special foundations for installation. The machines are simply bolted to the factory floor and connected to electrical and pneumatic/hydraulic (depending on model) supplies and dust extraction. In addition, the low noise level during operation means there is no need for a sound enclosure. If the factory layout changes, the resaw can easily be re-sited.

Precision cutting is ensured by the solid ‘vibration-free’ construction combined with the effective sawblade straining system and pressure sawguides, with the tensioned thin gauge wide bandsaw blade resulting in narrow saw kerf and therefore increased yield. The radial arm provides constant pressure throughout the full operating range for accurate feeding of varying timber dimensions.

Heavy-duty cast iron pulleys give long service life between resurfacing, with cleaning fluid automatically delivered to the pad and scraper system to control of resin and sawdust build-up on the pulleys and the blade. Integrated ducting and extracting points are provided for efficient removal of sawdust. These machines are fitted with a solenoid-controlled drip feed system with automatic cut-off to provide the correct flow of cleaning fluid to lubricate the felt pads. In tandem with scrapers fitted to the pulleys, the felt pads ensure the cleanliness of both the pulleys and the sawblade.

Strain is applied to the sawblade by a pneumatic or hydraulic cylinder, which applies force via a linkage when the lever is operated. For safety purposes a low-pressure switch is incorporated, which automatically removes power to the main drive motor power (so the machine stops running) if pressure drops to an unsatisfactory level.

Infinitely variable feed speed

Automatic feed unit operation

HMI control

Foot pedal override for feed unit

Heavy duty multi-roller fence

Pressure sawguide system

Pneumatic saw straining

Cleaning system for sawblades and pulleys

Idle horizontal table rollers at infeed and outfeed

Make an enquiry about the Stenner ST100R Resaw

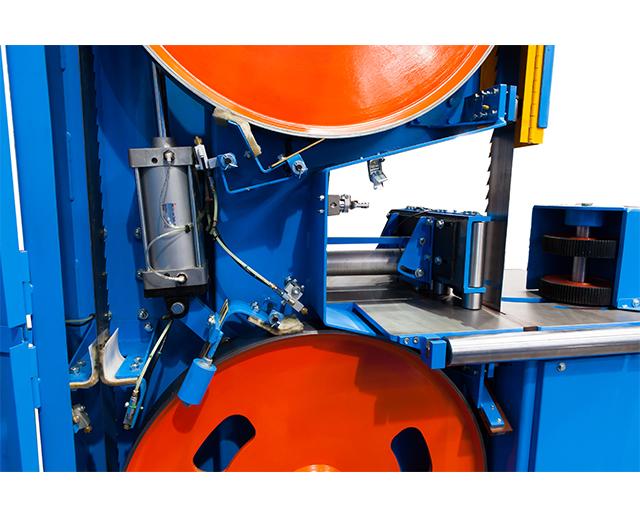

Stenner ST100R pulleys

Large pulley system provides high sawing torque and speed.

Pneumatic saw straining

Pneumatic straining allows pressure to be applied and released from the saw quickly and efficiently.

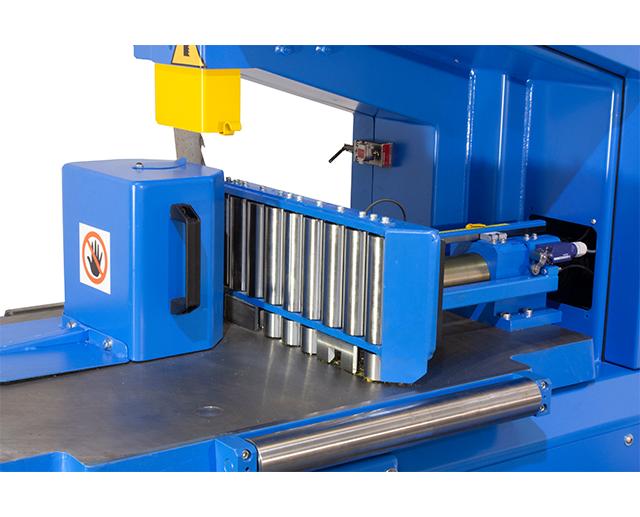

Heavy duty multi roller fence

Fence provides a stable moving surface to keep cuts even and straight.

| Maximum cutting height | 400mm |

|---|---|

| Maximum cutting width | 510mm |

| Working height | 955mm |

| Motor | 15kW |

| Blade | 100 x 0.8mm |

| Table tilt | 0 to 35° |

| Wheel Ø | 850mm |

| Feed speed | 5-60m/min |

| Dust extraction | 1 x 150mm, 1 x 80mm |

| Weight | 1500kg |

Specifications are subject to change without notice.

World leader in wide bandsaw technology