- Products

- Saws

- Edgebanding

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

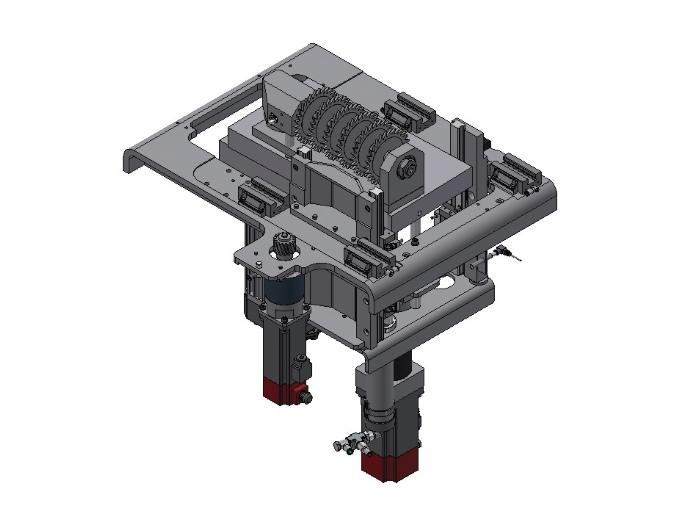

The Vitap Point Grooving is designed for rapid and precise production of acoustic and sound absorbing panels by means of CNC sawing.

- Ability to groove up to 6 grooves simultaneously.

- Variety of grooving head shapes are available as an option to suit all acoustic panel designs

- Quick-change HSK coupling

- Modern and easy to use programming software

- Low running costs due to no vacuum pumps

- Enclosed working area for reduced noise emissions

- Excellent dust extraction

- Small footprint - 4.3m²

Make an enquiry about the Vitap Point Grooving CNC

- Overview Overview and features

- Specs Specifications

- Related Related Products

- More Further Information

Standard grooving head

The standard grooving head features 6 sawblades with 32mm central intervals. Custom grooving heads can be made on request as an option. Quick-change HSK couplings allow rapid changing of the blades.

| Motor | 2.8kW |

|---|---|

| Spindle speeds | 7000 |

| Drilling head | Standard: 6 Saws (1x6 @ 32mm intervals) |

| X, Y, Z working area | Unlimited x 1250 x 50mm |

Max/min working area(mm): X=Unlimited/450, Y=1250/150, Z=50/12

Specifications are subject to change without notice.

Visit Vitap's youtube channel for more details on the Company and the products available

Create smarter with Vitap - quality specialist machinery from Italy designed to enhance production