Lowering Barriers to Prefabrication

At Jacks we’re often asked a very simple question by laypeople that have just seen a masterpiece of prefabrication on an episode of Grand Designs UK. It goes something like “Why on earth aren’t we doing this sort of stuff here?!” While uptake is improving in our corner of the world, there are a few problems specific to New Zealand that have slowed the adoption of panelised and modular construction.

Firstly, we’re a land of small businesses - the average builder in NZ lacks scale to take on the overhead and risk of a production facility. It’s the unfortunate reality that the barrier to entry is often just as high for a small volume builder as it is for a large producer. The other is that frankly, as an industry we’re a long way behind! It’s easy to look at the sophisticated prefabrication operations in Germany and Scandinavia and wonder how we can get from here to there - The jump is just too far for a lot of companies.

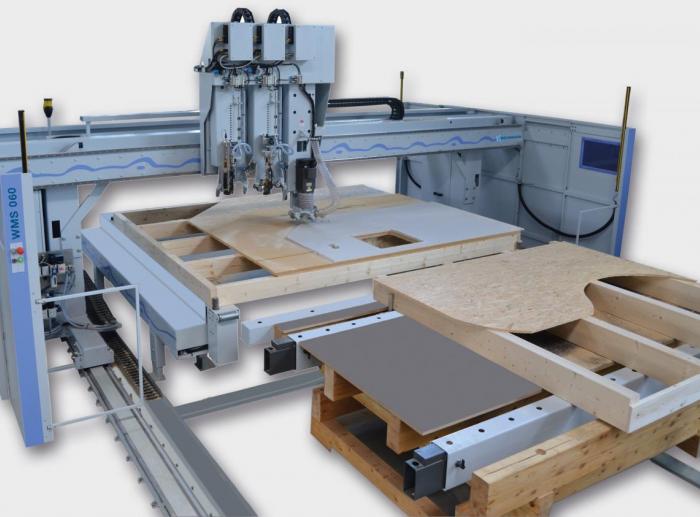

Weinmann’s new WMS060 CNC Multifunction Bridge is step towards addressing this, and bringing technology within reach of smaller operations. The machine processes wall, roof, and floor elements and will be available from December for around half the cost of previous entry level products of this quality.

The machine is based on the same chassis as the higher specification equipment that suits more industrial scale customers, and can staple, nail, and route penetrations. If you don’t want to take the step into a full detailing CAD package, for simple products the machine can be programmed directly from paper plans with a new onboard software tool. Fully automatic data transfer from CAD is still possible as well.

The WMS060 still has all the advantages of a CNC bridge - various worktables can be employed under the machine, including the popular two table butterfly configuration. Alternatively, for a truly barebones start, a startup customer can make a single worktable themselves, and Weinmann can supply the plans and clamping elements, which will be reused when upgrading to a more industrial solution. This means the space requirements are minimal – only 90m2 for a single 12m table machine, or around 190m2 for a two table operation.

Prefabrication is now becoming established around NZ, and we’ve already seen several of NZ’s bigger players enter this space. With the construction boom showing no signs of abating, Weinmann’s WMS060 brings advanced technology to within reach of any forward-thinking small business in NZ.

To find out more about Jacks and Weinmann check out our Offsite solutions page or get in touch with Richard Jack at richard.jack@jacks.co.nz.