- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

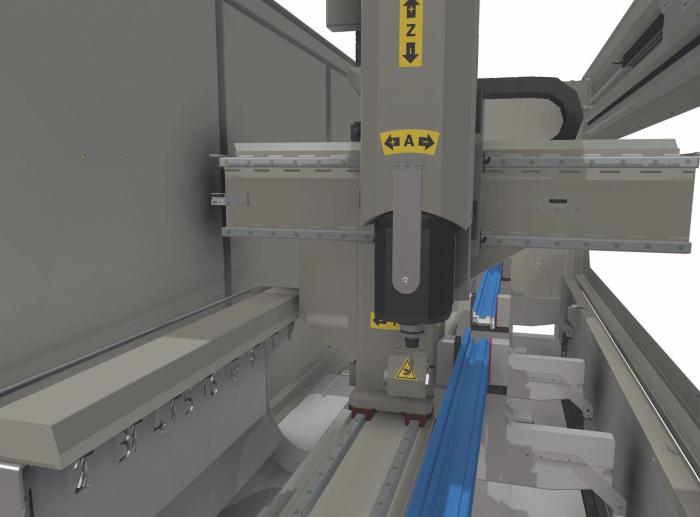

The Pertici P104 CNC Vertical Machining Centres are designed for drilling, milling, taping and end notching operations in several materials including:

• Aluminium Extrusions

• Light Gauge Steel Profiles

• uPVC Profiles

• Composite Profiles

The P104 can access three faces (top, back, front) and the two ends of a profile and perform various operations on any of these faces in a single program.

Using a total of four axis the machine can manipulate the spindle to all almost unlimited possibilities without operator interference. Programming is simple yet powerful thanks to the in house developed Pertici PCAM software that manages all aspects of the machines operation. Tool changes are completely automatic as is the position of all material clamps.

The machining head moves in longitudinal, transversal directions by brushless motors with rack and pinion system allowing the movement on ball bearings rails and slides to achieve very high precision. The vertical axis is driven by a super precise recirculating ball screw and brushless motor. The rotation of the spindle motor between -90° to +90°allows machining operation on all faces of the profile at any angles.

The P104 is ideal for either complex “one off” jobs, several variations on the same job or mass production of the same job. This machine can quickly change from one job to another or repetitively replicate the same cut continuously.

Make an enquiry about the Pertici P104 – 4 Axis CNC Machining Centre

Main spindle

The spindle is rated S1 for continuous processing. The winding of the spindle creates high torque even at low speeds for machining industrial aluminium profile and thin steel. An adjustable lubrication nozzle guarantees a consistent thin supply of lubricant directly to the tool during the milling process.

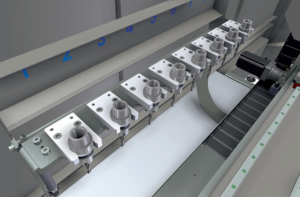

Automatic clamps

Positioning of the clamps is fully automatic using the main carriage to position each clamp. Automatic clamp positioning is fast and eliminates the chance of operator error causing a crash between the spindle and clamps. Pertici clamps specifically design for CNC machining. The clamps are compact yet robust. The compactness of the clamps enables processing of small workpieces close to the clamps where maximum stability of the workpiece is required. Ensuring clean and accurate machining. • 4 x Clamps as standard • Clamping range: 120 x 260mm in 4 axes. 225 x 260mm in 3 axes. Option to increase clamping range to 280 x 260mm in 3 axes. • Additional clamps available as an option

Tool magazine

8 position tool magazine positioned in the middle of the machine for quick tool changes. The spindle does not need to travel to one end of the CNC to make tool changes.

• Max. tool diameter 120mm

Control unit

The control unit is positioned on the left side of the machine. Fan-less industrial PC with Ethernet connection. • 21” full HD monitor • Standard keyboard & mouse

| Maximum tool Ø | 120mm milling blade |

|---|---|

| Dimensions (L x W x H) | 435 x 175 x 214cm |

| Spindle speeds | 20,000rpm |

| Main spindle | 5kW (6.7hp) |

| Tool changer | Automatic 8 tool magazine |

| X, Y, Z working area | 3,450 x 790 x 400mm |

| Axis speed (X, Y, Z) | 50 x 50 x 15m/min |

| Air consumption | 165L/min |

| Weight | 1800kg |

Specifications are subject to change without notice.

P104 – 4 Axis CNC Machining Centre

|

AIM 4310 Aluminium CNC

|

|

|---|---|---|

| Weight | 1800kg | 1950 kg |

| Spindle speeds | 20,000rpm | 18,000 rpm |

| X, Y, Z working area | 3,450 x 790 x 400mm | 4000 x 350 x 335 mm |

| Dimensions (L x W x H) | 435 x 175 x 214cm | 158 X 510 X 212cm |

| Main spindle | 5kW (6.7hp) | 7.5kW HSD |

| Tool changer | Automatic 8 tool magazine | 8 station linear |

Pertici is a global leader in technology for the processing of aluminum and PVC extrusions