- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

A versatile machine for timber frame construction

Equipped with a 12-slot tool changer, the WMS120 manufactures wall, roof and floor elements of a consistently high quality. The multifunction bridge allows nailing, stapling of panels and battens, as well as sawing, trimming and drilling of window and door cutouts and electrical outlets, all to be performed fully automatically.

- Short setup times and comprehensive processing thanks to a 12-slot tool changer

- Equipped for the future: Respond flexibly to changing market conditions with tool change technology

- Fully automatic transfer of data from all popular CAD programs for timber work

- Easy to operate with Homag’s intuitive powerTouch user interface

- Increased efficiency thanks to structured production processes

- Fast assembly on site thanks to the uniformly precise design of the elements

- Equipped with a chuck (also available with two chucks) for a fastening unit (stapling/nailing device) of your choice

- The fully automatic tool changer provides space for up to 12 tools, which can be selected according to individual requirement

- High performance thanks to the 18.5-kW tool spindle

- The highest safety standards: Light barriers and motion detectors ensure that the machine is stopped automatically if the operator is in the danger zone

- Can be integrated into a production line at any time

Make an enquiry about the Weinmann WMS 120 Multi-function bridge

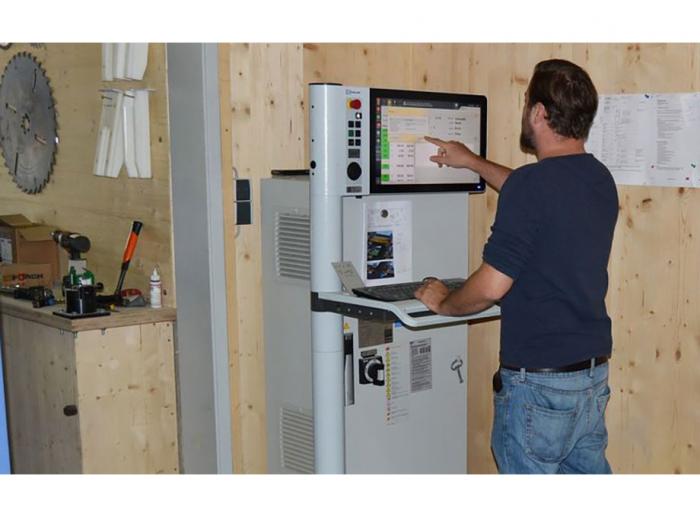

Easy operation with the intuitive operation concept powerTouch

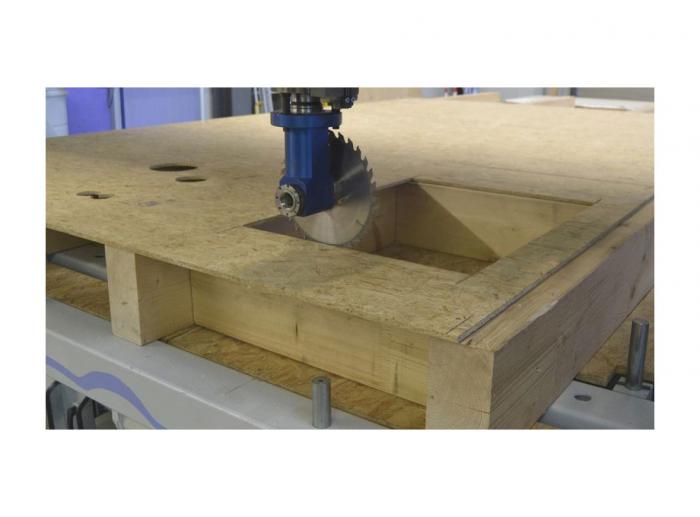

Trims windows, doors and socket openings

Multifunction bridge with sawing unit Flex 5

Equipped to the customers requirement, the tool changer offers space for 12 tools

Equipped to the customers requirement, the tool changer offers space for 12 tools

Specifications are subject to change without notice.

Solid wood processing for prefabrication & house-building.