- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

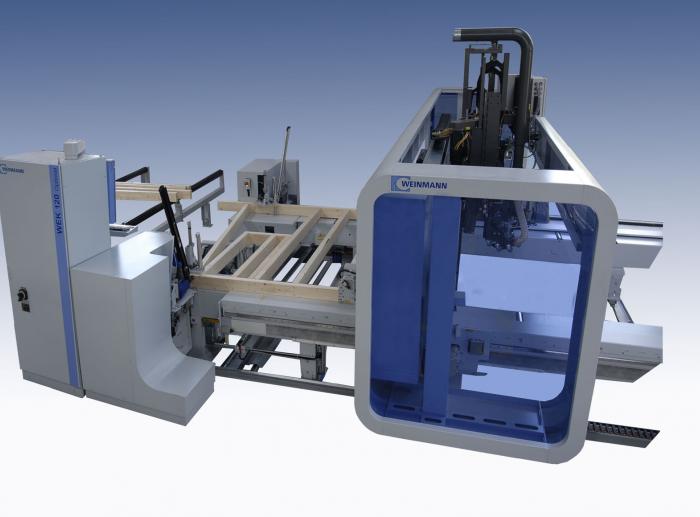

The WEK120 Combi wall system - a combination of a framing station and multi-function bridge for the production of semi-closed wall and gable elements in timber frame construction.

Made in Germany, the WEK120 allows precision manufacture of prefabricated wall-elements up to 12m long and 3.2m wide (3.8 as an option).

- High quality, minimal floor space requirement and ergonomics:

- 1 operator

- Less space but also more performance

- Automatic width adjustment

- Stud clamping system with CNC controlled nail guns for different nailing patterns

- Practical gable manufacturing for more flexibility

- Fully automated squaring of panels

- Unique barrier-free safety concept

- Wide compatibility with CAD/CAM design software

Weinmann's WEK120 offers a wide range of features to suit the wall element production you need. Options include:

- Noggin station for lengthwise studs and stopping system for gable elements

- Two cross cut saws for top and bottom plate

- Ink-Jet unit for marking

- Nail-plate station

- And much more...

Make an enquiry about the Weinmann WEK Combi-Wall System

Maximum quality and accuracy with minimal labour and floor space requirement

The frame work assembly and element sheeting can take place at one work station.

The framework is adjusted, clamped and fastened automatically by the WEINMANN stop alignment system. Lengthwise positioning is fully automated with the CNC controlled outfeed system.

Flexible and efficient processing according to your needs

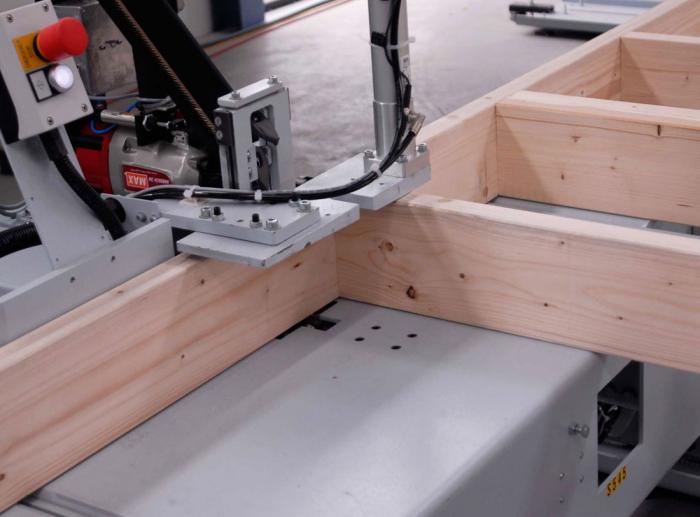

A CNC-driven multifunction bridge mounted on the outfeed gripper can automatically travel across the element to fasten the sheeting in a high speed operation.

CNC controlled nail guns provide flexibility for different nailing patterns to suit your materials

Noggin station for simple production of gable elements

An optional noggin station allows for simple insertion of noggins, and the accurate production of angled elements when required.

Batten-fixing made easy

Automated batten-location means the machine moves to the correct location, waits for operator to insert the batten, and then nails the batten according to a pre-configured pattern.

Pin-point accuracy with CNC-controlled clamping

Working from your CAD/CAM design files, the WEK120 features rock-solid clamping and flexible fixing patterns to ensure your wall-element is the same as the design file.

Every stud in the right place

Positive stops in the X-axis means it's easy for the operator to locate every stud exactly where it belongs.

Specifications are subject to change without notice.

Solid wood processing for prefabrication & house-building.