- Products

- Saws

- Edgebanding

- Brushing

- Sharpening & Grinding

- Extraction

- CNC

- Planing & Moulding

- Sanding

- Mortice & Tenon

- Peanut Connectors

- Portable tools

- Combination

- Drilling & Boring

- Aluminium

- Press & Clamp

- Handling Equipment

- Accessories

- Tooling

- Finger Jointing

- Shredding

- Scanning

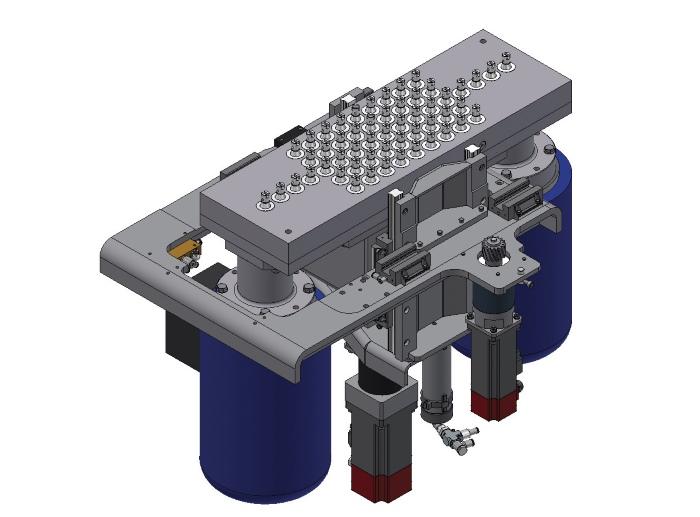

The Vitap Point Acoustic is designed for rapid and precise production of acoustic and sound absorbing panels by means of CNC boring.

- Ability to drill up to 55 holes every 4 seconds

- Variety of drilling head shapes are available as an option to suit all acoustic panel designs

- Quick-change drill chucks

- Modern and easy to use programming software

- Low running costs due to no vacuum pumps

- Enclosed working area for reduced noise emissions

- Excellent dust extraction

- Small footprint - 4.3m²

Make an enquiry about the Vitap Point Acoustic CNC

- Overview Overview and features

- Specs Specifications

- Related Related Products

- More Further Information

Standard boring head

The standard boring head features 55 drills (11 x 5) with 32mm central intervals. Custom boring heads can be made on request as an option. Quick-change couplings allow rapid changing of the drill bits.

Vitap Acoustic overview demonstrating quick chance drill chucks and drilling with various diameter drills and materials.

Vitap Acoustic working with foam materials (guarding removed for visibility purposes)

| Maximum cutting depth | 45mm |

|---|---|

| Motor | 8kW |

| Spindle speeds | 2800rpm |

| Drilling head | Standard: 55 Spindle (11x5 @ 32mm intervals) |

| X, Y, Z working area | Unlimited x 1250 x 50mm |

Specifications are subject to change without notice.

Visit Vitap's youtube channel for more details about the Company and products.

Create smarter with Vitap - quality specialist machinery from Italy designed to enhance production